Last updated: 25/06/2024 17:05:27

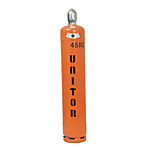

ACETYLENE A-40 FILLING

Product Code

- Product group:

- 710

- Product number:

- 905026

In combination with Oxygen (O₂) Acetylene (C₂H₂) is used for cutting and welding of steel. We will provide this product in the unique and global WSS cylinder exchange program.

Product information

Acetylene mixed with air is explosive within 2.2% to 85% by volume. Avoid releasing acetylene into the air and ensure good ventilation where acetylene cylinders are stored or used. When acetylene cylinders are transported horizontally and placed vertically again after transport, a period of at least 24 hours before using the cylinders for gas extraction must be obeyed. This to ensure that the acetone inside the cylinder redistributes in a correct way. When cylinders are used too quickly after placing them vertical again the following can happen: * When opening the top valve, large amounts of acetone can come out. The customer might interpret this as water/oil because acetone feels slippery on the skin. Opening the top valve without a fitted regulator should not be standard practice as this can create a fire hazard. * When a regulator is fitted with twinhose and torch, the lighted flame will be very unstable due to the presence of acetone droplets in the gas. This is often referred to as "spitting".

Solution is to let the cylinder rest for at least 24 hours (depending on temperature; colder environment might require longer time).

Features

- Colourless and slightly lighter than air

- It is non-toxic, but has an anesthetic effect if inhaled

- Acetylene is highly flammable

- When mixed with oxygen for welding, the flame temperature will reach 3100º C

Benefits

- Multi applications for ship maintenance like welding, cutting, brazing, soldering and heating.

- Suitable for AC-Ox Gas Distribution System

- For your safety, the product is delivered in a Unitor exchange cylinder complete with barcode and unique cylinder serial number.

- We trace and track all cylinders using our system to give you peace of mind.

- We offer global availability through our Global Exchange Programme.

Specification

General

| Cylinder Type | A-40 |

|---|---|

| Invent Hazard Material (IMO/EU) classification | C-18 |

Physical properties

| Colour | Maroon |

|---|

Dimensions/Weight

| Connection [Size/ Type] | G 3/4" R.H. INT. |

|---|---|

| Diameter [mm] | 230 |

| Gross Weight [kg] | 73 |

| Height [mm] | 1360 |

| Weight [kg] | 6.2 Net |

Technical data

| Connection [inch] | G 3/4" R.H. INT. side |

|---|---|

| Purity | >98% |

| Volume (l) | 40 |

Performance data

| Acetone contents | 12.4kg |

|---|---|

| Gas Capacity [m³] | 6.2kg |